By Isabella Andrade, Apparel Merchandising and Management Undergraduate Student and Research Assistant

Working with Wool Fibers

For the past year of my undergraduate college experience, I had the opportunity to work with different types of wool materials from U.S. sheep farms as part of Cal Poly Pomona’s USDA Education research project.

My first task as a research assistant was to learn the basics of analyzing wool fibers and properties to be knowledgeable about the materials. I was first exposed to working with wool in 2023 at the LA County Fair, where Cal Poly Pomona’s Apparel Merchandising and Management research team demonstrated hand spinning to community members. Using a drop spindle, we spun several yards of yarns, which were then made into a woven textile using a table loom. Different colored wool fibers were used to make a multi-colored textile adding an element of surface interest to the final product. The various colors came from different sheep breeds including Merino, Shetland, Romney, and Navajo Churro sheep. The wool was sourced during 2020-2023 as part of Dr. Trejo’s AMM 4630: Apparel Research Project course.

Spinning Wool Fibers from Various Sheep Breeds

Following the LA County Fair exhibit, I was given several batches of top from Cactus Hill Farm in Colorado, and Fox & Hound Merino Sheep farm in New York. This included CVM and Merino wool. I created single ply and 2-ply yarns. I had the freedom to mix and match the various colors to my liking when plying the yarn.

My main goal when spinning the yarn was to make it as consistent as possible in terms of thickness. While spinning the different colors of yarn – white, black, grey, and brown – I noticed small differences during the process in the way that the fibers spun together. The white wool, which was from the Merino sheep, was the easiest to spin as the fibers were more flexible when pulling them apart so that the yarn could be a consistent thickness. On the other hand, this ease of flexibility also meant that the fibers would break more easily, so I had to connect the fibers more frequently during the spinning process. This could be attributed to the characteristics of Merino wool being one of the finest wool fibers. In comparison, the Navajo Churro wool was the coarsest, and most difficult to pull apart during the spinning process.

LA County Fair Home Arts Award

By Spring 2024, I spun over 20 yards of wool yarns, which were displayed at the LA County Fair for nomination under the Home Arts Award. I placed third in the category of hand-spun yarns. Additionally, my professor and mentor, Dr. Trejo nominated me for the Surface Design Association Outstanding Student Award. This award was for my extensive work with yarn spinning that contributed towards the textiles developed during 2023 and 2024. I received a certificate of recognition.

Using Fiber Art at Cal Poly Pomona’s Fashion Tech Camp

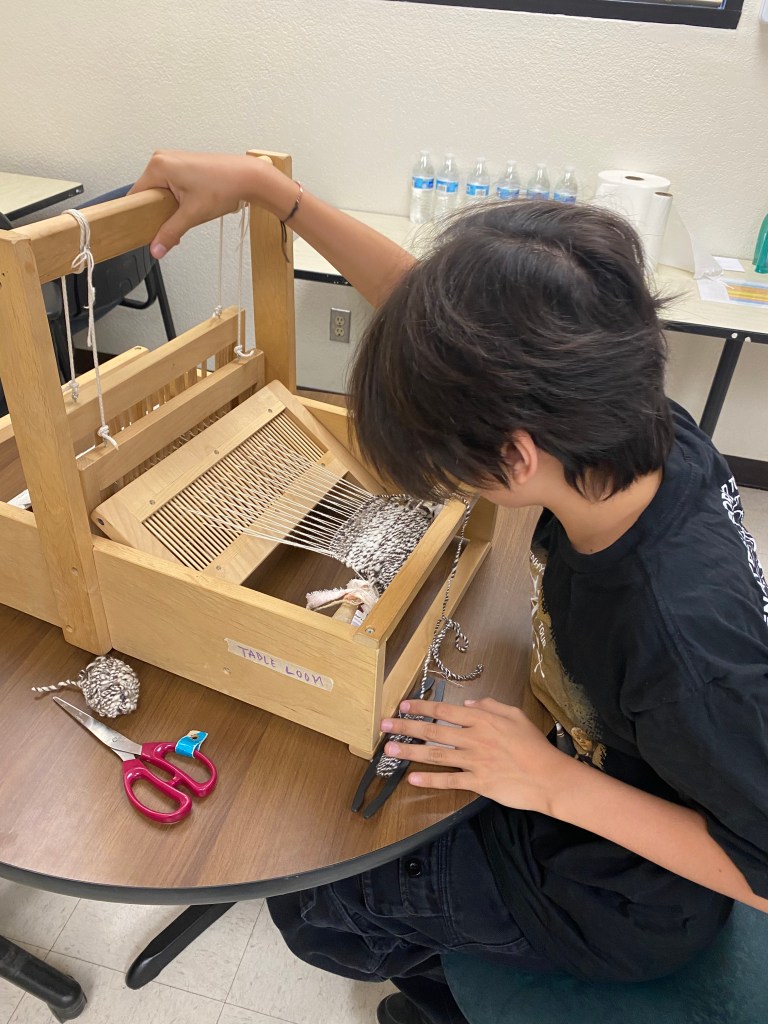

The yarns peers and I spun were also displayed and used during the departments first AMM Fashion Tech camps. We helped campers learn about fiber arts. Many of the campers were very interested in the process that the fibers undergo – beginning with shearing the sheep and ending with a finished textile. We helped the students spin the yarn and ply it afterwards. We also had the opportunity to allow the campers to use the table loom to contribute to the textile we started last year.

Overall, my experience as a student research assistant has been fulfilling and very educational. Working alongside Dr. Trejo and my peers has taught me several valuable skills such as collaboration, mentoring, research techniques, and fiber arts. Before working in this position, I never knew how large the fiber arts community really is. The Cal Poly Pomona Wool Exhibit at the LA County Fair allowed me to meet several individuals who also work with wool to make textiles of their own. This was a great opportunity to connect with others of different age groups and backgrounds over a common interest. I am grateful to have had the experience of being able to educate younger students about fiber arts and their relevance to the fashion industry today. I hope to learn more through my future endeavors in wool outreach programs.

This work was supported by a Hispanic-Serving Institutions Education Grants Program (HSI) Grant no. 2020-38422-32253 from the USDA National Institute of Food and Agriculture.